Wide Range of Pultrusion Products for Efficient Manufacturing

At our company, we offer an extensive selection of pultrusion products tailored for the pultrusion process. Pultrusion is a continuous and highly automated closed-moulding technique known for its cost-effectiveness in producing constant cross-sectional parts at high volumes.

How Pultrusion Works:

In pultrusion, continuous fibers are pulled through a resin bath, where they blend with a catalyst. Next, they pass through pre-forming fixtures where the section is partially shaped, and excess resin is removed. The final step involves passing the material through a heated die, defining the sectional geometry and finish of the end product.

Due to its precision and consistency in cross-section, resin dispersion, fiber distribution, and alignment, pultrusion enables the creation of exceptional composite structural materials. The profiles produced through this process can rival traditional metal profiles in terms of strength and weight, commonly found in materials like steel and aluminum.

Benefits of Using Pultruded FRP Sections

- Corrosion Resistant

- Weather Resistant

- Lightweight

- High Strength

- Electromagnetic Transparency

- Non-Conductive

- Electrically Insulating

- Easy to Fabricate & Install

- High Dimensional Stability

- Flame Retardant

.webp)

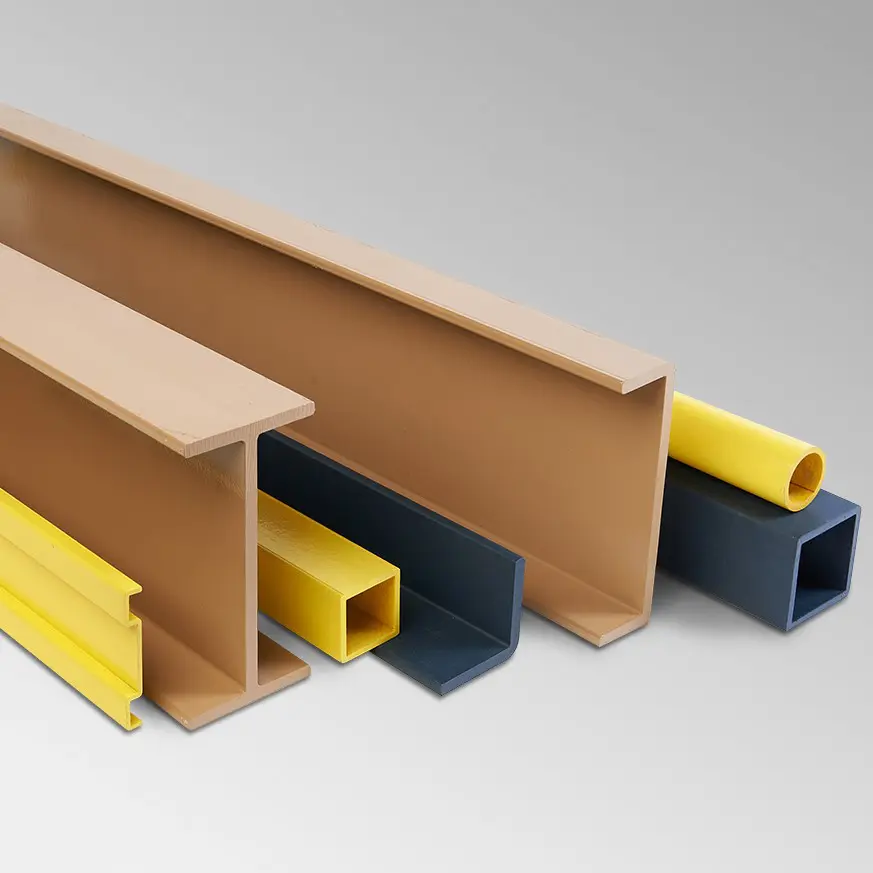

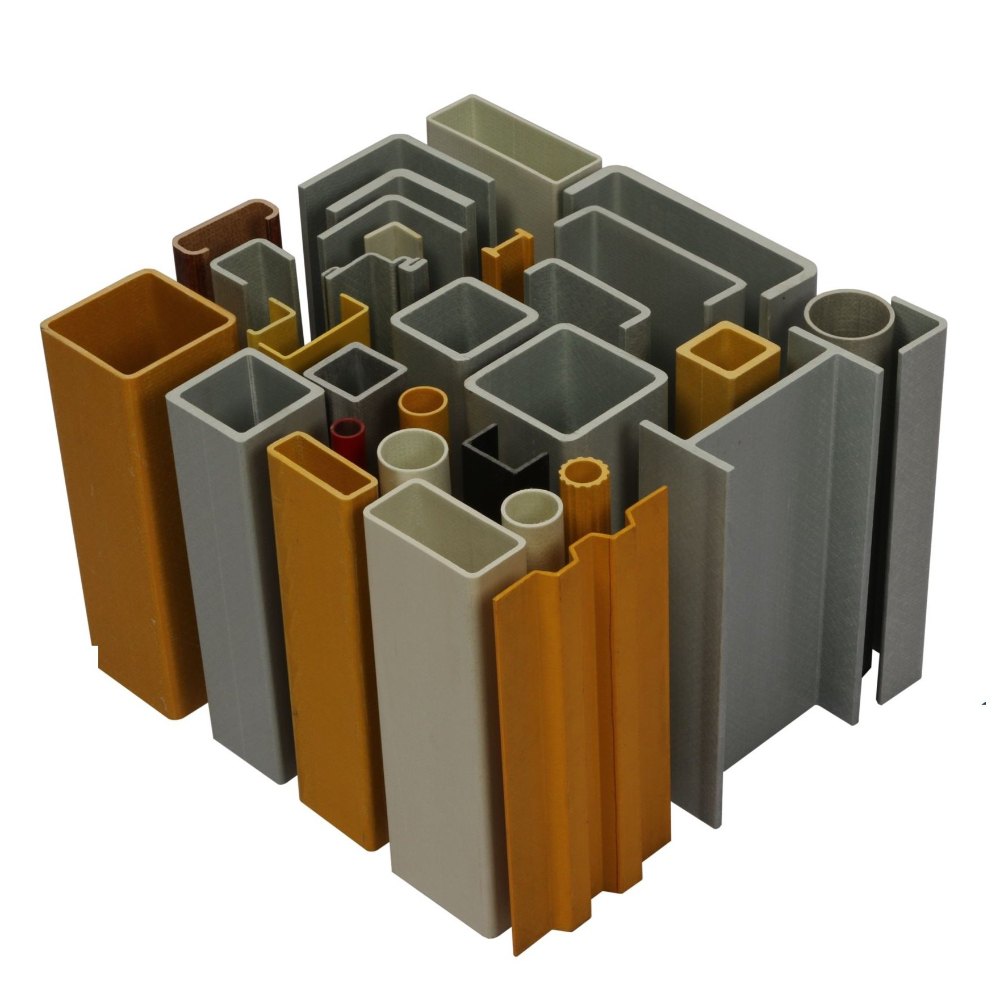

Pultrusion Product Range

Pultrusion is the most cost-effective method for the production of fiber-reinforced composite structural profiles. It brings high performance composites down to commercial products such as light-weight corrosion free structures, electrical non-conductive systems, off-shore platforms and many other innovative new products.

Our pultrusion products range include round rods, rectangles, squares, ‘I’ sections, ‘T’ sections, angles, channels, dog bone profiles, dove tail sticks and spacers, corner profiles, hallow sections, etc.

Structural Shapes

Pultruded Structural Shapes are good alternative over conventional metal structural shapes & Offers ideal solution against corrosion problems failed in industrial environment.

Applications

- walkways

- platforms

- columns

- trusses

- structural supports

- purline

Ladders

NJ Engitech has developed ladders with fiberglass or Aluminium steps to satisfy the requirement of clients. These Ladders are available in different colours & up to 35 feet length.

Applications:

- wall supported ladders

- Stairways

- Working Platforms

- Monkey Ladders With or Without cage

Electrical Insulation Material

Various types of pultruded arms, Rods, Flats, Corners & end pieces offers very goods electrical insulation property in combination with high mechanical strength corrosion resistance & all weather resistance for indoor & Outdoor applications. These Variety of pultruded products are available with polyester, Vinylester & Epoxy Resins.

Applications

- Bus bar support

- Dry type Transpormer Spacers

- 11KV/33KV Cross Arms

- Electrical insulation Requirements.

Consumer Product Range

NJ Engitech has development wide range of pultruded products to offer attractive solution in industrial application & in Commercial & Consumer Product Range.

Applications

- Door Frames

- Storage Racks

- Window Lineals

- Poles etc

| Features | Description | Benefits | Applications |

| Strong | Unit strength in tension & compression is approx. 20 x that of steel when these properties are combined on the basis of unit density | Optional strength as desired. Exceptionally high impact strength reduces damage potential | Structural process equipment support. Tank supports. Cooling tower ancillaries. Flooring supports. Trusses & joints. |

| Light Weight | Density of pultruded components is about 20% of steel and 60% of aluminium | Higher performance at less weight. Lower shipping, handling & installation costs. Less operational energy demand. | Automotive leaf springs & bumpers. Prefabricated walkways & platforms. Bus components. |

| Corrosion Resistant | Unaffected by exposure to a great variety of corrosive environment & chemicals. | Minimum maintenance costs. Long term safety. Longer life. | Chemical plant hand railings, gratings, walkways & bridges. Cable trays. Pipe supports. |

| Electrical Insulation | Provides strength & rigidity with dielectric properties. | Lesser no. of components. Non-magnetic & safe. Predictable insulation values for wide range of frequencies. | Ladders, Cable trays. Switch gear components. Mounting braces and backboards. |

| Thermal Insulation | Pultruded components have a low thermal conductivity, 1/250 of aluminium & 1/60 of steel. | educes installation thickness. Eliminates condensation problems. Reduces energy operation requirements. | Bulk head frames. Walk in refrigerator door jams. Window frames. Insulated roll up panel doors. |

| Consolidation | Many individual components can be combined into a large profile. | Reduced assembly cost. Reduced inventory. Fewer parts improve reliability. | Window latch supports. Roll up door |

| Dimensional Stability | Pultruded components are highly resistant to warping stretch/swelling over a wide range of temperature & stresses. | No permanent deformation under high stress. Close tolerances. | Spring bumpers. Crossing gate arms. Scrubber components. |

| Safety | The pultruded components are very strong & safe to work with. They are microbes and insect proof. | Many gratings suffer from the problem of microbes etc. due to wet or unhygienic working conditions. | This property makes them ideal choice for pharmaceutical & food industries. |

LIST OF PULTRUSION PRODUCTS

| SR. NO. | PRODUCT | SIZE | REMARKS |

| FRP ROD | |||

| 1 | FRP ROD | 16 MM | |

| 2 | FRP ROD | 22 MM | |

| 3 | FRP ROD | 24 MM | |

| 4 | FRP ROD | 33.5 MM | |

| FRP TUBE | |||

| 5 | FRP TUBE | 24 X 19 MM | |

| 6 | FRP TUBE | 22 X 17 MM | |

| 7 | FRP TUBE | 36 X 30 MM | |

| 8 | FRP TUBE | 44 X 38.2 MM | |

| 9 | FRP TUBE | 23 X 18 MM | |

| 10 | FRP TUBE | 30.5 X 25.5 MM | |

| 11 | FRP TUBE | 37.75 X 32.25 MM | |

| 12 | FRP TUBE | 44.75 X 39.25 MM | |

| 13 | FRP TUBE | 51.75 X 46.25 MM | |

| 14 | FRP TUBE | 50 X 44.5 MM | |

| 15 | FRP TUBE | 50 X 40 MM | |

| 16 | FRP TUBE | 48.3 X 38.3 MM | |

| 17 | FRP TUBE | 57 X 48 MM | |

| 18 | FRP TUBE | 62 X 54.2 MM | |

| 19 | FRP TUBE | 75 X 67 MM | |

| 20 | FRP TUBE | 24 X 13 MM | |

| 21 | FRP TUBE | 16 X 10 MM | |

| FRP C – CHANNEL | |||

| 22 | FRP CHANNEL | 300 X 50 X 4 MM | |

| 23 | FRP CHANNEL | 300 X 75 X 4 MM | |

| 24 | FRP CHANNEL | 200 X 75 X 4 MM | |

| 25 | FRP CHANNEL | 200 X 75 X 3 MM | |

| 26 | FRP CHANNEL | 200 X 75 X 3 MM | |

| 27 | FRP CHANNEL | 200 X 50 X 4 MM | |

| 28 | FRP CHANNEL | 200 X 50 X 3 MM | |

| 29 | FRP CHANNEL | 170 X 45 X 5 MM | |

| 30 | FRP CHANNEL | 150 X 40 X 6 MM | |

| 31 | FRP CHANNEL | 150 X 50/20 X 6 MM | |

| 32 | FRP CHANNEL | 150 X 75 X 3 MM | |

| 33 | FRP CHANNEL | 150 X 75 X 4 MM | |

| 34 | FRP CHANNEL | 150 X 50 X 4 MM | |

| 35 | FRP CHANNEL | 150 X 50 X 3 MM | |

| 36 | FRP CHANNEL | 100 X 30 X 6 MM | |

| 37 | FRP CHANNEL | 100 X 50 X 4 MM | |

| 38 | FRP CHANNEL | 100 X 50 X 3 MM | |

| 39 | FRP CHANNEL | 100 X 30 X 4 MM | |

| 40 | FRP CHANNEL | 100 X 30 X 3 MM | |

| 41 | FRP CHANNEL | 106 X 20 X 3 MM | |

| 42 | FRP CHANNEL | 75 X 30 X 6 MM | |

| 43 | FRP CHANNEL | 75 X 25 X 3 MM | |

| 44 | FRP CHANNEL | 50 X 25 X 3 MM | |

| 45 | FRP CHANNEL | 38 X 11 X 3.5 MM | |

| 46 | FRP CHANNEL | 34 X 34 X 6 MM | |

| FRP RECTANGULAR SECTION | |||

| 47 | FRP SECTION | 75 X 40 X 3 MM | |

| 48 | FRP SECTION | 75 X 40 X 5 MM | |

| 49 | FRP SECTION | 50 X 25 X 3 MM | |

| 50 | FRP SECTION | 150 X 50 X 3 MM | |

| FRP SQUARE SECTION | |||

| 51 | FRP SECTION | 50 X 50 X 3 MM | |

| 52 | FRP SECTION | 50 X 50 X 5 MM | |

| FRP SECTION | |||

| 53 | FRP BENCH SECTION | 85 X 30 X 3.5 MM | |

| 54 | HOLLOW SQUARE TUBE | 25 X 25 X 13 MM | |

| 55 | HOLLOW SQUARE TUBE | 25 X 25 X 19 MM | |

| 56 | FRP HANDRAIL SECTION | 65 X 45 X 4 MM | |

| 57 | FRP SERRATED TUBE | 50 X 43 MM | |

| 58 | FRP Z SECTION | 94 X 30 X 3 MM | |

| 59 | I-BEAM | 25 X 15 X 4 MM | |

| 60 | I-BEAM | 38 X 15 X 4 MM | |

| 61 | FRP ANGLE | 60 X 5 MM | |

| 62 | FRP ANGLE | 45 X 4 MM | |

| 63 | FRP ANGLE | 50 X 3 MM | |

| 64 | FRP FLAT | 157 X 3 MM | |

| 65 | FRP FLAT ( TOE GUARD) | 100 X 12 X 3 MM | |

| 66 | FRP FLAT | 100 X 3 MM | |

| 67 | FRP FLAT | 25 X 6 MM | |

| 68 | FRP DOOR FRAME | 100 X 50 X 3 MM | |

| 69 | FRP DOOR FRAME | 90 X 45 X 3 MM | |

| ANY CUSTOMIZED PROFILE SIZES CAN BE DEVELOPED ON REQUEST | |||

| SR. NO. | PRODUCT | SIZE | WT. KG/MTR. |

| FRP TUBE | |||

| 1 | FRP TUBE | OD 36 X ID MM | 0.576 |

| 2 | FRP TUBE | OD 24 X ID 19 MM | 0.350 |

| 3 | FRP TUBE | OD 22 X ID 17 MM | 0.324 |

| 4 | FRP TUBE | 0.324 MM | 0.312 |

| 5 | FRP TUBE | OD 44 X ID 38.2 MM | 0.693 |

| 6 | FRP TUBE | OD 30.5 X ID 25.5 MM | 0.407 |

| 7 | FRP TUBE | OD 37.75 X ID 32.25 MM | 0.560 |

| 8 | FRP TUBE | OD 44.75 X ID 39.25 MM | 0.672 |

| 9 | FRP TUBE | OD 51.75 X ID 46.25 MM | 0.784 |

| 10 | FRP TUBE | OD 50 X ID 44.5 MM | 0.756 |

| 11 | FRP TUBE | OD 57 X ID 48 MM | 1.380 |

| 12 | FRP TUBE | OD 62 X ID 54.2 MM | 1.320 |

| 13 | FRP TUBE | OD 24 X ID 13 MM | 0.592 |

| 14 | FRP TUBE | OD 16 X ID 10 MM | 0.227 |

| FRP C – CHANNEL | |||

| 15 | FRP CHANNEL | 300 X 50 X 4 MM | 3.10 |

| 16 | FRP CHANNEL | 300 X 75 X 4 MM | 3.42 |

| 17 | FRP CHANNEL | 150 X 40 X 6 MM | 2.52 |

| 18 | FRP CHANNEL | 150 X 75 X 3 MM | 1.72 |

| 19 | FRP CHANNEL | 150 X 75 X 4 MM | 2.230 |

| 20 | FRP CHANNEL | 150 X 50 X 4 MM | 1.90 |

| 21 | FRP CHANNEL | 150 X 50 X 3 MM | 1.45 |

| 22 | FRP CHANNEL | 38 X 11 X 3.5 MM | 0.342 |

| 23 | FRP CHANNEL | 40 X 11 X 3.5 MM | 0.350 |

| 24 | FRP CHANNEL | 100 X 30 X 6 MM | 1.82 |

| 25 | FRP CHANNEL | 100 X 30 X 4 MM | 1.20 |

| 26 | FRP CHANNEL | 100 X 30 X 3 MM | 0.902 |

| 27 | FRP CHANNEL | 75 X 30 X 6 MM | 1.53 |

| 28 | FRP CHANNEL | 75 X 25 X 3 MM | 0.804 |

| 29 | FRP CHANNEL | 50 X 25 X 3 MM | 0.550 |

| 30 | FRP CHANNEL | 34 X 34 X 6 MM | 1.141 |

| 31 | FRP CHANNEL | 85 X 30 X 3.5 MM | 1.119 |

| FRP RECTANGULAR SECTION | |||

| 32 | FRP SECTION | 75 X 40 X 3 MM | 1.32 |

| 33 | FRP SECTION | 50 X 25 X 3 MM | 0.855 |

| FRP HOLLOW SQUARE TUBE | |||

| 34 | FRP SECTION | 25 X 25 X 18.5 MM | 0.602 |

| 35 | FRP SECTION | 25 X 25 X 13 MM | 0.853 |

| FRP ANGLE | |||

| 36 | FRP ANGLE | 50 X 50 X 3 MM | 0.570 |

| 37 | FRP ANGLE | 25 X 15 X 3 MM | 0.190 |

| 38 | FRP ANGLE | 60 X 60 X 5 MM | 1.14 |

| FRP DOOR FRAME | |||

| 39 | FRP FRAME | 100 X 50 X 3 MM | 1.28 |

| 40 | FRP FRAME | 100 X 50 X 4 MM | 1.64 |

| 41 | FRP FRAME | 90 X 45 X 3 MM | 1.18 |

| FRP WINDOW FRAME | |||

| 42 | FRP FRAME | 50 X 20 X 3.5 MM | 0.611 |

| 43 | FRP FRAME | 38 X 20 X 3 MM | 0.383 |

| 44 | FRP FRAME | 0.383 MM | |

| FRP SQUARE SECTION | |||

| 45 | FRP SECTION | 50 X 50 X 3 MM | 1.14 |

| 46 | FRP SECTION | 50 X 50 X 5 MM | 1.90 |

| FRP SECTION | |||

| 47 | FRP FLAT | 25 X 6 MM | 0.294 |

| 48 | I-BEAM | 25 X 15 X 4 MM | 0.387 |

| 49 | I-BEAM | 38 X 15 X 4 MM | 0.550 |

| ANY CUSTOMIZED PROFILE SIZES CAN BE DEVELOPED ON REQUEST | |||