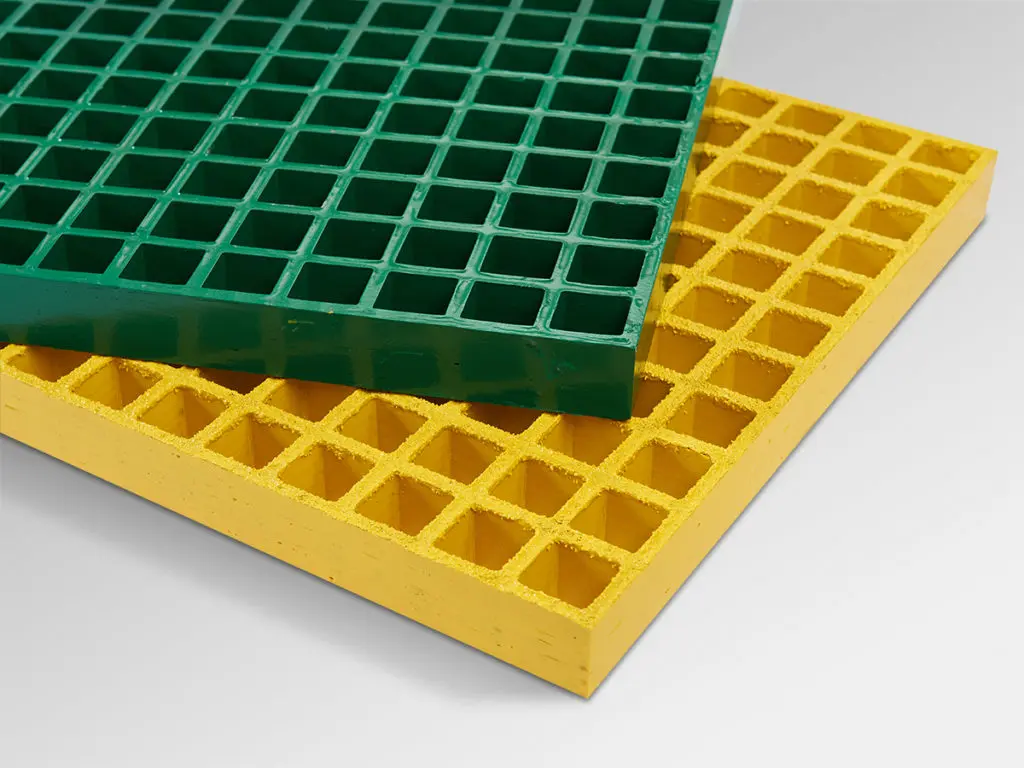

FRP Moulded Grating Manufacturer

NJ Engitech's FRP Molded Grating is made by skilled professionals in an open, heated mold system. They lay down layers of continuous glass roving in both directions and soak them completely with resin. This special process creates strong plates that resist corrosion and have strength in two directions.

Our FRP Molded Grating is designed to withstand tough conditions, offering reliable corrosion resistance. The square mesh structure is strong in two directions, making it efficient and minimizing waste when cutting panels. The high ratio of resin to glass ensures a long service life, even in the toughest situations.

Advantages of Moulded Gratings

| Description | NJ Engitech Grating | Hot Dip Galvanised | Stainless Steel |

| Strength to weight ratio | Excellent | Average | Average |

| Life span | Excellent | Good | Very Good |

| Life Cycle Cost effectiveness | Excellent | Good | Good |

| Chemical Resistivity | Excellent | Good | Excellent |

| Electrical Non-conductivity | Excellent | Poor | Poor |

| Rust proof Features | Excellent | Average | Excellent |

| Handling | Very easy | Difficult | Difficult |

| Installation cost | Very low | High | High |

| Anti skid | Available | Not Available | Not Available |

| Colour selection | Available | Not Available | Not Available |

Why NJ ENGITECH FRP / GRP Grating

At NJ Engitech, our FRP (Fiber Reinforced Polymer) products come with a range of fantastic qualities:

-

Corrosion Resistance: They can handle almost all chemicals and harsh environments without damage.

-

Lightweight: They are four times less dense than steel, making them easy to handle and install.

-

Non-Conductive: They won't carry any electric current, ensuring electrical safety.

-

Impact Resistance: They bounce back to their original shape without permanent bending or distortion.

-

Maintenance-Free: No need for painting or frequent cleaning, reducing upkeep efforts.

-

Long Life Cycle: Their durability ensures the lowest overall cost throughout their long lifespan.

-

Easy Installation: No welding is required during installation, making it hassle-free.

-

Aesthetic: They come in attractive colors, enhancing the appearance of your facility.

-

Easy to Clean: They are completely rust and corrosion-proof, allowing for easy washing.

Application of FRP Moulded Gratings

| Industry/Application | Industry/Application | Industry/Application |

|---|---|---|

| Industrial | EMI/RFI Testing | Recreation |

| Marine | Pollution Control | Building Construction |

| Mining | Power Plants | Metal Finishing |

| Chemical | Pulp & Paper | Water/Waste Water |

| Oil & Gas | Offshore | Transportation |

| Electrical | Radar | Plating |

Resin Selection Chart

| RESIN TYPE | GRATING TYPE | DESCRIPTION | APPLICATION |

| Vinyl Ester | Type VE | Superior corrosion resistance | Environment with high corrosion problems. |

| Flame resistant Vinyl Ester | Type VE-FR | Superior corrosion & Flame resitance | Environment with high corrosion requiring better flame resistance. |

| Isophthalic Polyester | Type IP | Industrial grade corrosion resistance | Used in the environments of normal or less concentration inorganic acid, alkali, etc |

| Flame resistant Isophtalic polyester | Type IP-FR | Industrial grade corrosion & Flame resistance | Used in les concentrated inorganic acidic areas requiring better flame resistance. |

| Orthophthalic polyester | Type OP | Moderate grade corrosion resistance | For use in environment which requires water & weather proof solution. |