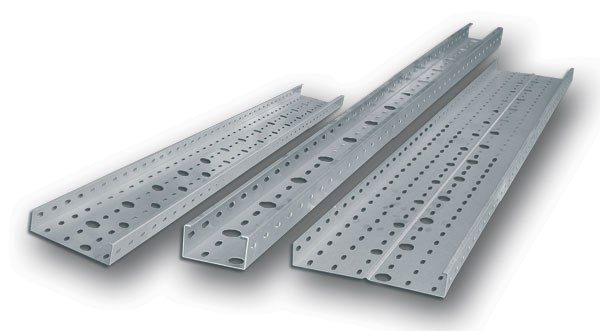

Ladder Cable Tray

Our FRP Ladder Type Cable Trays are a testament to engineering excellence. They are meticulously crafted by assembling a variety of Pultruded Cross Sections, Side Runners, and Rungs, resulting in a cable management solution that surpasses all expectations.

Ladder cable trays are a rugged and highly adaptable cable management solution. They consist of a series of parallel transverse members (rungs) connected by longitudinal side rails. This design forms a "ladder" structure, providing excellent support for heavy cables and conduits in various industrial and commercial applications.

Innovative FRP Cable Tray Solutions by NJ Engitech Global

At NJ Engitech Global, we specialize in the design and manufacturing of top-quality FRP (Fiber Reinforced Plastic) cable trays and accessories. Our cable trays are meticulously engineered by our team of experts to provide robust support for power cables and control cables in both indoor and outdoor applications.

The range of cable trays includes-

- Ladder type FRP cable tray

- Trough type frp cable tray

- Channel type frp cable tray

As a trusted supplier and exporter of FRP cable trays, NJ Engitech Global offers a wide variety of FRP products and cable trays to customers in India and around the world. Our products are not only durable but also lightweight, making them easy to install and transport.

Unique Features of FRP Cable Trays

- Fire retardant

- Excellent weather ability – UV stabilized

- Non corrosive

- Non erosive

- Non magnetic

- Easy to install

- Easy to transport

- Light weight

- Maintenance free

- Load bearing capacity

Advantages of FRP Perforated Cable Trays

All the frp range of perforated products is corrosion resistant. These products are lighter in weight and can be easily moved and transported from one place to another. You don’t need earthing for these products. These are made of UV resistant materials. The thermal conductivity is very low. These are halogen free and non toxic and have long life cycle.

Industries using our products

| Industry | Application Areas |

|---|---|

| Refineries | Oil Processing, Chemical Handling |

| Offshore Platforms | Oil and Gas Exploration and Production |

| Oil and Gas Industry | Drilling, Production, Transportation |

| Electricity Distribution | Power Generation, Transmission, Distribution |

| Effluent Treatment Plants | Wastewater Management, Environmental Protection |

| Marine and Shipping | Shipbuilding, Ports, Maritime Transport |

| Foot Bridges | Pedestrian Walkways, Structural Engineering |

| Manufacturing | Industrial Production, Manufacturing Processes |

| Bakery | Food Production, Baking |

| Chemical and More | Chemical Processing, Various Industrial Applications |

Standard specification is available as per below table

| Width | Side Runner Ht. | Rung Width | Design Load UDL | Material |

| 100mm | 77 / 100 / 150 | 50mm | 10kg / mtr. | Polyester / Viny |

| 150mm | 77 / 100 / 150 | 75mm | 12kg / mtr. | Polyester / Viny |

| 200mm | 77 / 100 / 150 | 100mm | 15kg / mtr. | Polyester / Viny |

| 250mm | 77 / 100 / 150 | 150mm | 18kg / mtr. | Polyester / Viny |

| 300mm | 77 / 100 / 150 | 200mm | 25kg/mtr. | Polyester / Viny |

| 400mm | 77 / 100 / 150 | 300mm | 30kg/mtr. | Polyester / Viny |

| 450mm | 77 / 100 / 150 | 450mm | 40kg/mtr. | Polyester / Viny |

| 500mm | 77 / 100 / 150 | 500mm | 45kg/mtr. | Polyester / Viny |

| 600mm | 77 / 100 / 150 | 600mm | 50kg/mtr. | Polyester / Viny |